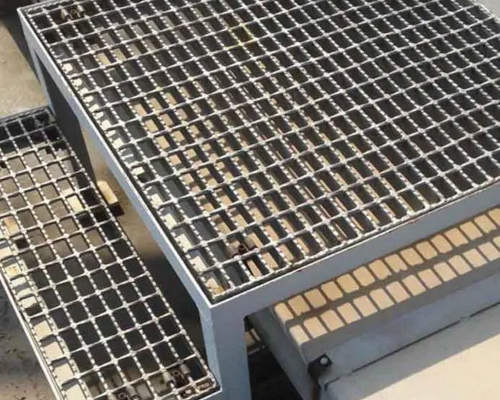

We manufacture gratings and treads for applications across industries. Our gratings are used for many applications such as steel flooring, access walkways, balconies, platforms, facades and much more.

We see it as our main responsibility to ensure that our products and solutions provide maximum safety for end-users. Our aim is that whether people walking across a bridge, along an access walkway, up a public stairway or on a maintenance platform, all feel safe as a matter of course.

We are the company with over 15 years of experience in the manufacturing and customization of steel gratings.

We have ISO certification and many years of experience, ensuring that our products are of the highest quality.

We have a strict quality control system to ensure that all our products meet your requirements. .

Gratings: Electroforged Gratings, Stainless Steel Gratings, Welded / Custom Made Gratings, Heavy Duty Gratings, Expanded Metal Gratings, FRP Gratings

Manufacturer and exporter of Pressure Welded Steel Gratings, Alloy Steel Expanded Metal Gratings, Mild Steel Electroforged Gratings, Custom Made Gratings, Heavy Duty Gratings.

Before the production process begins, our team of experts will consult with you to determine the best design for your project. We take into account the intended use of the final product, the dimensions and weight of the load, the environment in which it will be used, and any other relevant factors. This ensures that your steel gratings will be up to the task and will last for years to come.

The quality of the raw materials used is crucial to the quality of the final product. We only use the best materials available to create our steel gratings, ensuring that your product will meet or exceed your expectations. Also, all of our materials are sourced from sustainable and environmentally friendly suppliers.

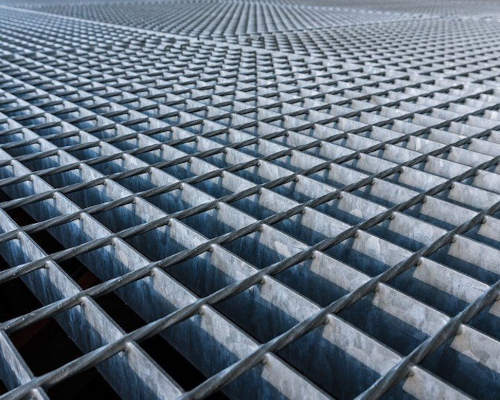

Once the design is finalized and the raw materials have been sourced, the manufacturing process can begin. The first step is pressure welding, in which panels are welded together to create the desired shape. This is done using a high-pressure welding machine that creates a strong, stable bond between the panels.

After the welding process is complete, the steel gratings are moved to the products workshop for finishing. Here, any necessary cuts or holes are made, and the gratings are given a final inspection to ensure that they meet our high standards. Once they have passed inspection, the gratings are ready to be shipped to our clients.

Speciality

We produce Perforated Cable Tray, Ladder Type Cable Tray, Stainless Steel Type Cable Tray, Cable Tray Duct, FRP Cable Tray

Read More

Best Products

Steel tiles for dairies, aluminium plants and maintenance shop also for the production line of textile industries. It is ideally suited for pallet and fork lift movement and where the heavy component is either manufacture of repaired.

Read More